Steel Nail

PRODUCT INTRODUCTION

Nails were formerly made of bronze or wrought iron and were crafted by blacksmiths and nailors. These crafts people used a heated square iron rod that they forged before they hammered the sides which formed a point. After reheating and cutting off, the blacksmith or nailor inserted the hot nail into an opening and hammered it.Later new ways of making nails was created using machines to sheer the nails before wiggling the bar sideways to produce a shank. For example, the Type A cut nails were sheared from an iron bar type guillotine using early machinery. This method was slightly altered until the 1820s when new heads on the nails' ends were pounded via a separate mechanical nail heading machine. In the 1810s, iron bars were flipped over after each stroke while the cutter set was at an angle. Every nail was then sheared off of taper allowing for an automatic grip of each nail which also formed their heads.[15] Type B nails were created this way. In 1886, 10 percent of the nails that were made in the United States were of the soft steel wire variety and by 1892, steel wire nails overtook iron cut nails as the main type of nails that were being produced. In 1913, wire nails were 90 percent of all nails that were produced.

Today's nails are typically made of steel, often dipped or coated to prevent corrosion in harsh conditions or to improve adhesion. Ordinary nails for wood are usually of a soft, low-carbon or "mild" steel (about 0.1% carbon, the rest iron and perhaps a trace of silicon or manganese). Nails for concrete are harder, with 0.5–0.75% carbon.

TYPES OF NAIL INCLUDE:

- ·Aluminum nails – Made of aluminum in many shapes and sizes for use with aluminum architectural metals

- ·Box nail – like a common nail but with a thinner shank and head

- ·Brads are small, thin, tapered, nails with a lip or projection to one side rather than a full head or a small finish nail.

- ·Floor brad ('stigs') – flat, tapered and angular, for use in fixing floor boards

- ·Oval brad – Ovals utilize the principles of fracture mechanics to allow nailing without splitting. Highly anisotropic materials like regular wood (as opposed to wood composites) can easily be wedged apart. Use of an oval perpendicular to the wood's grain cuts the wood fibers rather than wedges them apart, and thus allows fastening without splitting, even close to edges

- ·Panel pins

- ·Tacks or Tintacks are short, sharp pointed nails often used with carpet, fabric and paper Normally cut from sheet steel (as opposed to wire); the tack is used in upholstery, shoe making and saddle manufacture. The triangular shape of the nail's cross section gives greater grip and less tearing of materials such as cloth and leather compared to a wire nail.

- ·Brass tack – brass tacks are commonly used where corrosion may be an issue, such as furniture where contact with human skin salts will cause corrosion on steel nails.

- ·Canoe tack – A clinching (or clenching) nail. The nail point is tapered so that it can be turned back on itself using a clinching iron. It then bites back into the wood from the side opposite the nail's head, forming a rivet-like fastening.

- Shoe tack – A clinching nail (see above) for clinching leather and sometimes wood, formerly used for handmade shoes.

- ·Carpet tack

- ·Upholstery tacks – used to attach coverings to furniture

- ·Thumbtack (or "push-pin" or "drawing-pin") are lightweight pins used to secure paper or cardboard.Casing nails – have a head that is smoothly tapered, in comparison to the "stepped" head of a finish nail. When used to install casing around windows or doors, they allow the wood to be pried off later with minimal damage when repairs are needed, and without the need to dent the face of the casing in order to grab and extract the nail. Once the casing has been removed, the nails can be extracted from the inner frame with any of the usual nail pullers.

- ·Clout nail – a roofing nail

- ·Coil nail – nails designed for use in a pneumatic nail gun assembled in coils

- ·Common nail – smooth shank, wire nail with a heavy, flat head. The typical nail for framing

- ·Convex head (nipple head, springhead) roofing nail – an umbrella shaped head with a rubber gasket for fastening metal roofing, usually with a ring shank

- ·Copper nail – nails made of copper for use with copper flashing or slate shingles etc.

- ·D-head (clipped head) nail – a common or box nail with part of the head removed for some pneumatic nail guns

- ·Double-ended nail – a rare type of nail with points on both ends and the "head" in the middle for joining boards together. See this patent. Similar to a dowel nail but with a head on the shank.

- ·Double-headed (duplex, formwork, shutter, scaffold) nail – used for temporary nailing; nails can easily pulled for later disassembly

- ·Dowel nail – a double pointed nail without a "head" on the shank, a piece of round steel sharpened on both ends

- ·Drywall (plasterboard) nail – short, hardened, ring-shank nail with a very thin head

- ·Fiber cement nail – a nail for installing fiber cement siding

- ·Finish nail (bullet head nail, lost-head nail) – A wire nail with a small head intended to be minimally visible or driven below the wood surface and the hole filled to be invisible

- ·Gang nail – a nail plate

- ·Hardboard pin – a small nail for fixing hardboard or thin plywood, often with a square shank

- ·Horseshoe nail – nails used to hold horseshoes on hoofs

- ·Joist hanger nail – special nails rated for use with joist hangers and similar brackets. Sometimes called "Teco nails" (1+1⁄2 × .148 shank nails used in metal connectors such as hurricane ties)

- ·Lost-head nail – see finish nail

- ·Masonry (concrete) – lengthwise fluted, hardened nail for use in concrete

- ·Oval wire nail – nails with an oval shank

- ·Panel pin

- ·Gutter spike – Large long nail intended to hold wooden gutters and some metal gutters in place at the bottom edge of a roof

- ·Ring (annular, improved, jagged) shank nail – nails that have ridges circling the shank to provide extra resistance to pulling out

- ·Roofing (clout) nail – generally a short nail with a broad head used with asphalt shingles, felt paper or the like

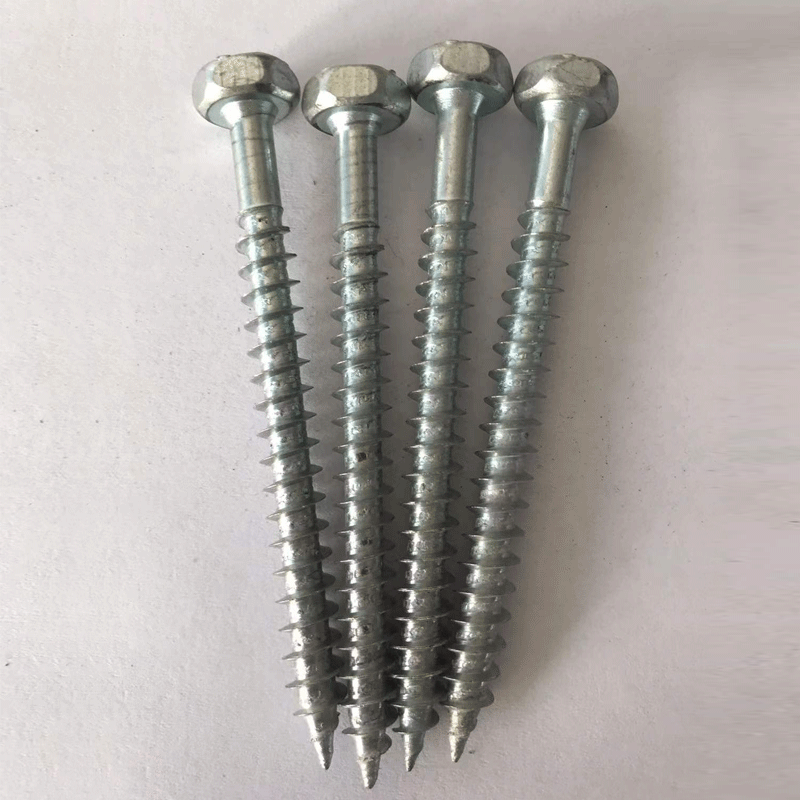

- ·Screw (helical) nail – a nail with a spiral shank - uses including flooring and assembling pallets

- ·Shake (shingle) nail – small headed nails to use for nailing shakes and shingles

- ·Sprig – a small nail with either a headless, tapered shank or a square shank with a head on one side.Commonly used by glaziers to fix a glass plane into a wooden frame.

- ·Square nail – a cut nail

- ·T-head nail – shaped like the letter T

- ·Veneer pin

- ·Wire (French) nail – a general term for a nail with a round shank. These are sometimes called French nails from their country of invention

- ·Wire-weld collated nail – nails held together with slender wires for use in nail guns

TERMINOLOGY:

- ·Box: a wire nail with a head; box nails have a smaller shank than common nails of the same size

- ·Bright: no surface coating; not recommended for weather exposure or acidic or treated lumber

- ·Casing: a wire nail with a slightly larger head than finish nails; often used for flooring

- ·CC or Coated: "cement coated"; nail coated with adhesive, also known as cement or glue, for greater holding power; also resin- or vinyl-coated; coating melts from friction when driven to help lubricate then adheres when cool; color varies by manufacturer (tan, pink, are common)

- ·Common: a common construction wire nail with a disk-shaped head that is typically 3 to 4 times the diameter of the shank: common nails have larger shanks than box nails of the same size

- ·Cut: machine-made square nails. Now used for masonry and historical reproduction or restoration

- ·Duplex: a common nail with a second head, allowing for easy extraction; often used for temporary work, such as concrete forms or wood scaffolding; sometimes called a "scaffold nail"

- ·Drywall: a specialty blued-steel nail with a thin broad head used to fasten gypsum wallboard to wooden framing members

- ·Finish: a wire nail that has a head only slightly larger than the shank; can be easily concealed by countersinking the nail slightly below the finished surface with a nail-set and filling the resulting void with a filler (putty, spackle, caulk, etc.)

- ·Forged: handmade nails (usually square), hot-forged by a blacksmith or nailor, often used in historical reproduction or restoration, commonly sold as collectors items

- ·Galvanized: treated for resistance to corrosion and/or weather exposure

- ·Electrogalvanized: provides a smooth finish with some corrosion resistance

- ·Hot-dip galvanized: provides a rough finish that deposits more zinc than other methods, resulting in very high corrosion resistance that is suitable for some acidic and treated lumber;

- ·Mechanically galvanized: deposits more zinc than electrogalvanizing for increased corrosion resistance

- ·Head: round flat metal piece formed at the top of the nail; for increased holding power

- ·Helix: the nail has a square shank that has been twisted, making it very difficult to pull out; often used in decking so they are usually galvanized; sometimes called decking nails

- ·Length: distance from the bottom of the head to the point of a nail

- ·Phosphate-coated: a dark grey to black finish providing a surface that binds well with paint and joint compound and minimal corrosion resistance

- ·Point: sharpened end opposite the "head" for greater ease in driving

- ·Pole barn: long shank (2+1⁄2 in to 8 in, 6 cm to 20 cm), ring shank (see below), hardened nails; usually oil quenched or galvanized (see above); commonly used in the construction of wood framed, metal buildings (pole barns)

- ·Ring shank: small directional rings on the shank to prevent the nail from working back out once driven in; common in drywall, flooring, and pole barn nails

- ·Shank: the body the length of the nail between the head and the point; may be smooth, or may have rings or spirals for greater holding power

- ·Sinker: these are the most common nails used in framing today; same thin diameter as a box nail; cement coated (see above); the bottom of the head is tapered like a wedge or funnel and the top of the head is grid embossed to keep the hammer strike from sliding off

- ·Spike: a large nail; usually over 4 in (100 mm) long

- ·Spiral: a twisted wire nail; spiral nails have smaller shanks than common nails of the same size