-

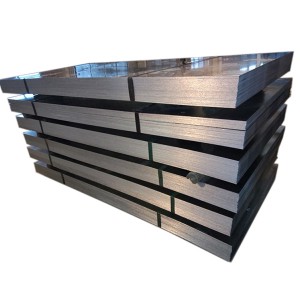

Cold Rolled Steel Coil or Sheets

Cold Rolled Steel Coil or Sheets

If you’ve been in construction or manufacturing, you know the importance of choosing the right material for your project. An increasingly popular material is cold rolled steel coil or sheet. In this blog post, we’ll explore the advantages of using this steel in your projects.

First, what is cold rolled steel? It is a steel that is processed at room temperature, usually below its recrystallization temperature. This process results in a harder, more durable material than hot-rolled steel produced at high temperatures.

So why should you consider using cold rolled steel in your projects?

1. Better surface finish: The surface finish of cold rolled steel is smoother than that of hot rolled steel. This makes it ideal for applications where appearance is important, such as automotive or consumer electronics.

2. Increased strength: Cold-rolled steel is generally stronger than hot-rolled steel. This is because the cold rolling process compresses and hardens the steel, making it more resistant to bending and other forms of deformation.

3. Increased precision: Cold rolled steel is more precise than hot rolled steel due to the tighter tolerances used in the cold rolling process. This makes it ideal for applications where precision is critical, such as in the aerospace or medical industries.

4. Better consistency: Cold-rolled steel is more consistent than hot-rolled steel in terms of thickness and flatness. This makes working with it easier and ensures a uniform look to your finished product.

5. Versatility: Cold-rolled steel has a wide range of applications, from structural steel to automotive parts to furniture. This versatility makes it a popular choice in many different industries.

Of course, there are some potential downsides to using cold-rolled steel. One is that it tends to be more expensive than hot rolled steel, which may be a consideration for some projects. Also, cold-rolled steel is more difficult to machine because it is harder and less ductile than hot-rolled steel.

But in general, the advantages of using cold-rolled steel are obvious. It is stronger, more precise, and more consistent than hot-rolled steel, and its smooth surface finish makes it ideal for applications where appearance is important. If you’re looking for a durable and versatile material for your next project, consider cold rolled steel coil or plate.

-

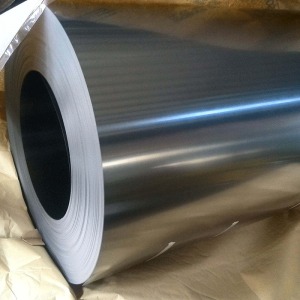

Cold Rolled Steel coil

Cold rolled steel is hot-rolled steel that has been cleaned of iron oxide scale (pickled) and reduced to a specific thickness through a series of rolling stands (tandem mill) or passed back and forth through a reversing rolling mill. The steel can be heated to controlled temperatures (annealing) depending on mechanical property requirements, and final rolled to the desired thickness.