-

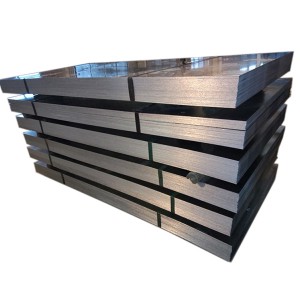

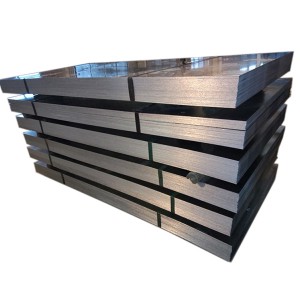

Ikhoyili Yensimbi Egoqiwe Ebandayo noma Amashidi

Ikhoyili Yensimbi Egoqiwe Ebandayo noma Amashidi

Uma uke waba sezokwakha noma wenza, uyakwazi ukubaluleka kokukhetha impahla efanele iphrojekthi yakho.Into ethandwa kakhulu yikhoyili yensimbi egoqiwe ebandayo noma ishidi.Kulokhu okuthunyelwe kwebhulogi, sizohlola izinzuzo zokusebenzisa le nsimbi kumaphrojekthi akho.

Okokuqala, iyini insimbi egoqiwe ebandayo?Kuyinsimbi ecutshungulwa endaweni yokushisa yasekamelweni, ngokuvamile ngaphansi kwezinga lokushisa layo lokuvuselela kabusha.Le nqubo ibangela into eqinile, ehlala isikhathi eside kunensimbi egoqwe eshisayo ekhiqizwa emazingeni okushisa aphezulu.

Ngakho-ke kungani kufanele ucabange ukusebenzisa insimbi egoqiwe ebandayo kumaphrojekthi akho?

1. Isiphetho esingcono sangaphezulu: Indawo engaphezulu yensimbi egoqiwe ebandayo ishelela kunensimbi egoqiwe eshisayo.Lokhu kuyenza ilungele izinhlelo zokusebenza lapho ukubukeka kubalulekile khona, njengezimoto noma ugesi wabathengi.

2. Amandla angeziwe: Insimbi egoqekayo ngokuvamile inamandla kunensimbi egoqwe ngokushisa.Lokhu kungenxa yokuthi inqubo yokuginqika ebandayo iyayicindezela futhi iqinise insimbi, iyenze imelane nokugoba nezinye izinhlobo zokuwohloka.

3. Ukunemba okukhulayo: Insimbi egoqiwe ebandayo inembe kakhulu kunensimbi egoqiwe eshisayo ngenxa yokubekezelelana okuqinile okusetshenziswe enqubweni yokugoqa okubandayo.Lokhu kuyenza ilungele izinhlelo zokusebenza lapho ukunemba kubaluleke khona, njengasemkhathini noma ezimbonini zezokwelapha.

4. Ukungaguquguquki okungcono: Insimbi egoqelwe ngokubanda ivumelana kakhulu kunensimbi egoqelwe eshisayo ngokuya ngokuqina nokucaba.Lokhu kwenza ukusebenza nayo kube lula futhi kuqinisekisa ukubukeka okufanayo kumkhiqizo wakho ophelile.

5. Ukuguquguquka: Insimbi egoqelwe ngamakhaza inezinhlobonhlobo zezinhlelo zokusebenza, kusukela kunsimbi yesakhiwo kuya ezingxenyeni zezimoto kuya kufenisha.Lokhu kuguquguquka kwenza kube ukukhetha okudumile ezimbonini eziningi ezahlukene.

Yiqiniso, kukhona ezinye izinto ezimbi ezingase zibe khona ekusebenziseni insimbi egoqwe ngokubanda.Enye ukuthi ivame ukubiza kakhulu kunensimbi egoqwe eshisayo, okungase kube ukucatshangelwa kwamanye amaphrojekthi.Futhi, insimbi egoqiwe ebandayo inzima kakhulu ukuyifaka ngomshini ngoba iqinile futhi incane i-ductile kunensimbi egoqwe eshisayo.

Kodwa ngokuvamile, izinzuzo zokusebenzisa insimbi ebandayo ziyabonakala.Inamandla, inembe kakhulu, futhi iyahambisana kakhulu kunensimbi egoqelwe ngokushisayo, futhi ukuphela kwayo okubushelelezi kuyenza ifanelekele izinhlelo zokusebenza lapho ukubonakala kubalulekile.Uma ufuna okokusebenza okuqinile nokuguquguqukayo kwephrojekthi yakho elandelayo, cabanga ikhoyili yensimbi egoqiwe ebandayo noma ipuleti.

-

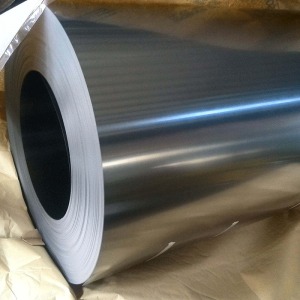

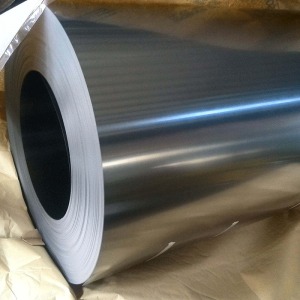

Cold Rolled Steel ikhoyili

Insimbi egoqiwe ebandayo iyinsimbi egoqwe eshisayo ehlanzwe esikalini se-iron oxide (efakwe emanzini anosawoti) futhi yehliswa ugqinsi oluthile ngochungechunge lwezinsimbi eziginqikayo (i-tandem mill) noma idluliselwe emuva naphambili ngesigayo esigoqayo.Insimbi ingashiswa kumazinga okushisa alawulwayo (i-annealing) kuye ngezidingo zempahla yemishini, futhi okokugcina kugingqelwe kubukhulu obufunekayo.